Wide range of Compressed Air Dryer is manufactured and supplied by us to our esteemed clients. This range comprises of Heatless Compressed Air Dryers, Compact/Mini Air Dryers and Refrigerated Air Dryers. The entire range is praised by the clients due to its phenomenal patterns and designs

REFRIGERATED AIR DRYERS

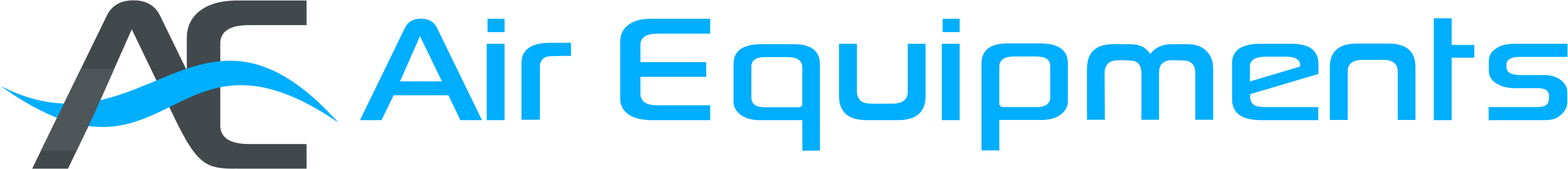

Refrigerated dryers are general purpose dryers, most economical being less running cost. Air Equipments refrigerant system is environmentally friendly in nature. Refrigeration dryer remove moisture from compressed air to the desired dew point temperature. The dryer includes two separate circuits like compressed air circuit & refrigeration circuit.

Working Principle

The saturated compressed air enters in air - to - air heat exchanger (Pre-cooler / Re-heater). Here the incoming hot air is cooled by the out going cold air. This is basically an energy saving heat exchanger. It reduces the load on the refrigeration system. The Pre-cooled incoming air enters in the Air-to- Refrigerant heat exchanger further reducing the air temperature to specified dew point 2°c- 4°c. The air leaving this evaporator is directed to the cyclone separators and water vapor Condensate liquid droplets removed automatically by Air Equipments Drain Valve. The Hot Gas by-pass valve maintains constant load to the refrigeration system.

Sailent Features

- Compact Design

- Running cost is Very Low

- Hot Gas by-pass circuit for partial Load.

- Maintains Constant Pressure Dew Point

- Auto Drain Valve Provided for cyclone separator

- Non-cyclic System

- Low Pressure Drop

- Environment Friendly system

- Compressor safety through maintain Low/High Constant Pressure

Note : High Pressure / flow range can be offered on request. Operating Pressure standard at 14kg/cm

COMPACT HEATLESS AIR DRYERS

Compact heatless air dryer works on the principal of absorption. regenerative air dryers use desiccant media absorbs moisture contaminate from compressed air. The desiccant media can be regenerated by purging air and remove moisture it collect and remove again and again. So the dryers of the compressed air achieved up to atmospheric -40˚c dew point. The traditional refrigeration heat less dryer does not provide sufficient air quality required for special application. Air Equipments regeneration heatless dryer contains smooth uniform achieved alumina balls size that prevents channeling of compressed air flow, which maintains low bed velocities. This maintains air contact time for efficient moisture removal and minimal pressure drops. Air Equipments have electronic control timer for pneumatically pilot valves are chosen for long life and high air flow. A pre filter. oil removing filter, after filter offering purification to 5 micron can be specified. Purge loss and pressure drop are kept at a minimum resulting in lower operating costs.

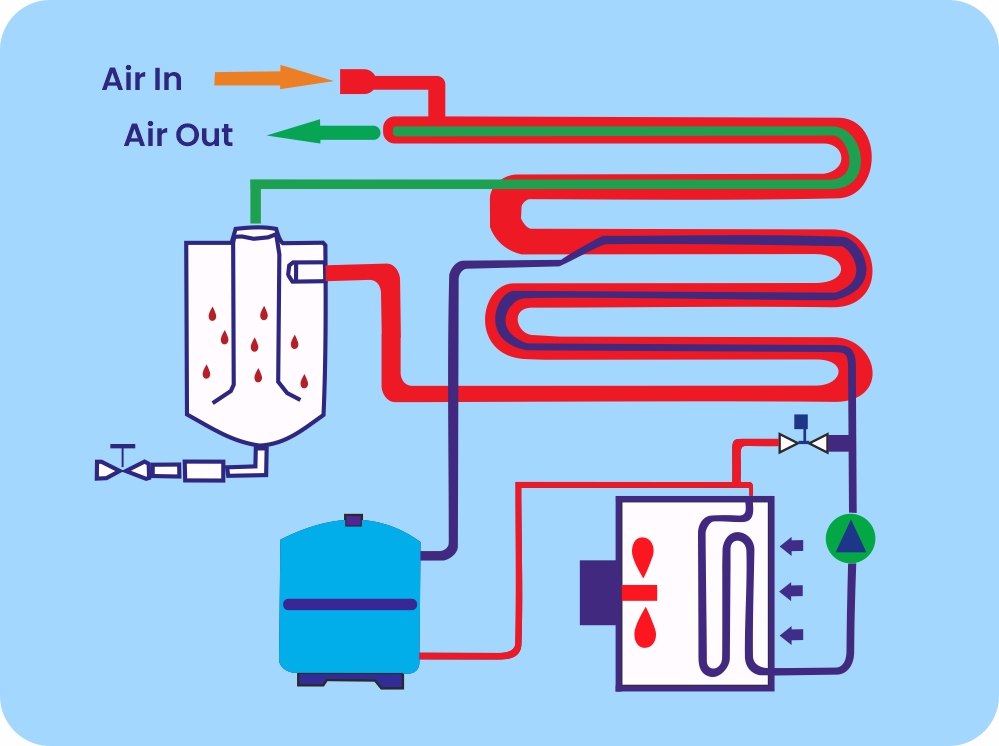

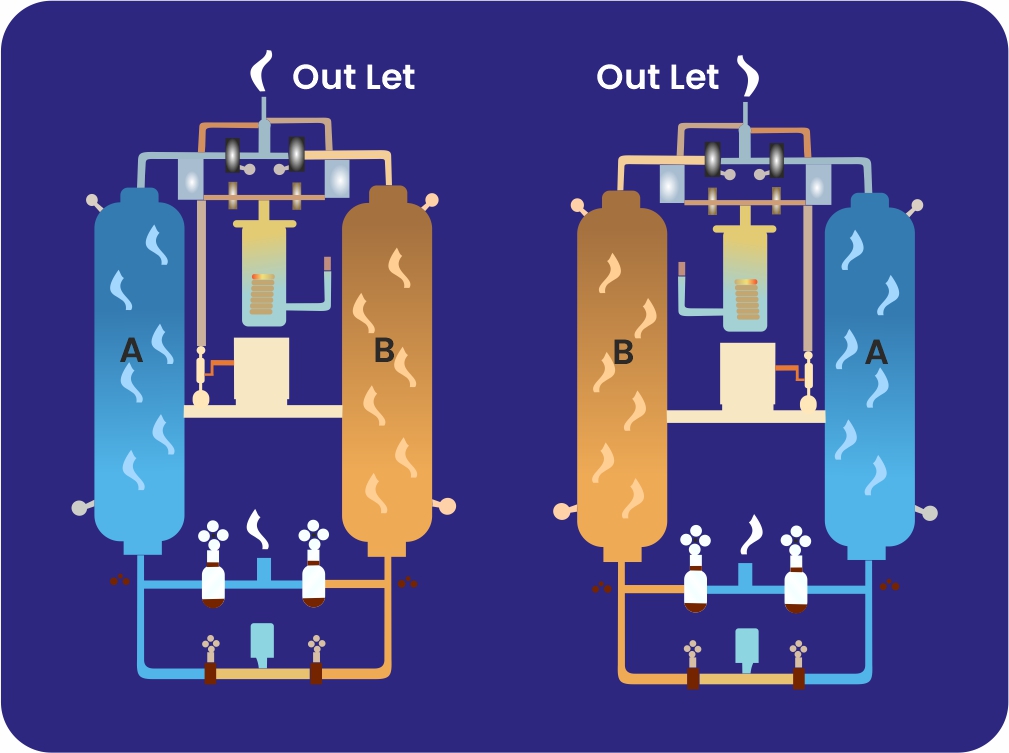

HEATLESS AIR DRYERS

Heat less dryer works on the principal of absorption. regenerative air dryers use desiccant media absorbs moisture contaminate from compressed air. The desiccant media can be regenerated by purging air and remove moisture it collect and remove again and again. So the dryers of the compressed air achieved up to atmospheric -40˚c dew point. The traditional refrigeration heat less dryer does not provide sufficient air quality required for special application. Air Equipments regeneration heatless dryer contains smooth uniform achieved alumina balls size that prevents channeling of compressed air flow, which maintains low bed velocities. This maintains air contact time for efficient moisture removal and minimal pressure drops. Air Equipments have electronic control timer for pneumatically pilot valves are chosen for long life and high air flow. A pre filter. oil removing filter, after filter offering purification to 5 micron can be specified. Purge loss and pressure drop are kept at a minimum resulting in lower operating costs

WORKING PRINCIPAL

During an operating cycle inlet air directed to pre filter, here moisture and dust particles are removed then air enters to oil removing filter here we remove flooded oil. As wet air flows through the desiccant tower bed the twin tower design of our dryers allows simultaneous compressed air drying and desiccant regenerated without interruption to the compressed air flow. At the end of the drying cycle the regenerated tower is re-pressurized and tower operation is reversed automatically. After tower change over wet inlet air is directed to the regenerated tower and the previously used desiccant is regenerated by the same process. A completed cycle of drying and regeneration is 10 minutes or 6 minutes timing is precisely controlled by Air Equipments electronic timer.

Applications:

Automobile Industries, Cement Industries, Chemical Plants, CNC Machine Shops, Foundries, Food Processing Units, Garment Units, General Engineering, Pharmaceuticals, Painting Units, Paper Mills, Packaging Units, Power Coating Units, Pet Bottle Units, Rice Mills, Sugar Industries, Textile Processing Units